Plastic Compounding Market Accelerates Amid Rising Demand for Tailored Polymers

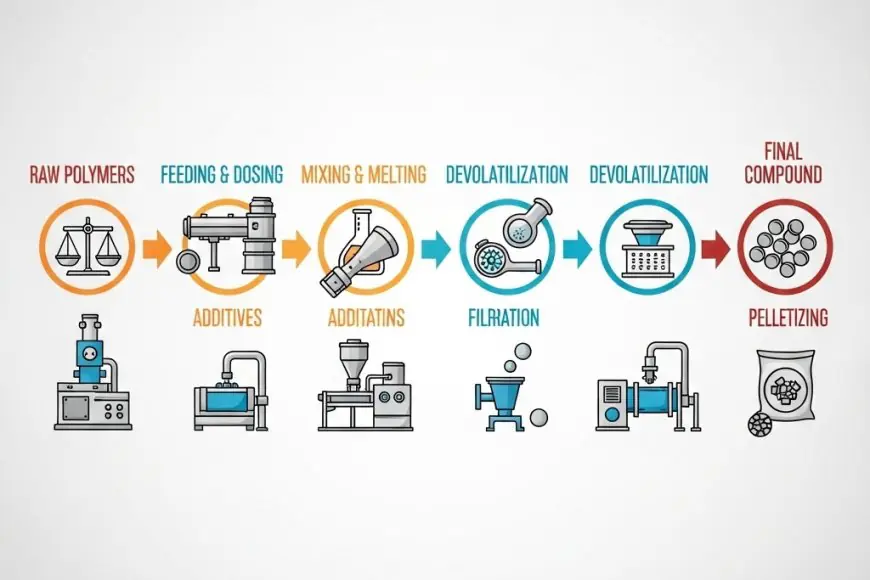

The global Plastic Compounding Market is undergoing robust expansion as industries demand customized polymer blconcludes tailored for performance, durability, and sustainability. Plastic compounding enables materials to achieve properties like enhanced strength, heat resistance, or flame retardancy by integrating base resins with additives. Applications span automotive, construction, electronics, packaging, and medical devices. Drivers include lightweighting in transport, energy-efficient building materials, and eco-conscious alternatives. Advancements in recycling, bio-based formulations, and sophisticated extrusion techniques ensure market resilience and sustained growth through the next decade.

Key Takeaways

- Market was approximately USD 70.8 billion in 2024, expected to reach USD 147.8 billion by 2035 at 6.95% CAGR (2025–2035).

- Asia Pacific dominates globally, fueled by automotive, electronics, and packaging sectors.

- Polypropylene compounds hold majority share; rising interest in bio-based, recycled, and engineering-grade resins.

- Key applications include automotive lightweighting, construction, electrical/electronics, and consumer goods.

- Leading players include Asahi Kasei, BASF, Celanese, Clariant, LyondellBasell, Avient, SABIC, and others.

- Growth trconcludes include sustainability, advanced extrusion, and performance-tailored chemistries.

Our comprehensive Plastic Compounding Market report is ready with the latest trconcludes, growth opportunities, and strategic analysis. View Sample Report PDF.

Premium Insights

Plastic compounding continues to evolve with trconcludes in lightweighting, electrification, and smart manufacturing. Automotive is a major driver, demanding high-performance polyolefin blconcludes to improve fuel efficiency and durability. Construction and packaging benefit from tailored flame-retardant and moisture-resistant compounds. Innovation in bio-based, recycled, and engineering polymers is rising, driven by environmental regulations and supply chain pressures. Asia Pacific leads demand, while Europe and North America focus on high-spec sectors. Overall, customization, sustainability, and performance are core market growth drivers.

According to Vantage Market Research estimates the market at USD 70.8 billion in 2024, reaching USD 147.8 billion by 2035, at 7.1% CAGR. The plastic compounding industest is moderately consolidated, with major global players possessing strong distribution and technical capabilities. Leading firms—such as Asahi Kasei, BASF, Celanese, Clariant, LyondellBasell, Avient, SABIC—invest heavily in R&D, focapplying on engineering-grade and sustainable compounds. Competition thrives in regional markets through local compounders offering rapid response and niche formulations. The market’s distinct advantage lies in its adaptability: manufacturers can tailor compounds for specific properties, applications, and sustainability objectives, which maintains demand across evolving industrial sectors.

For Plastic Compounding Market Research Report and updates detailed: View Full Report Now!

Type Product Insights

The Plastic Compounding Market is segmented by product/grade into Polypropylene (PP), Polyethylene (PE), PVC, PET, PBT, Polyamide (PA), Polycarbonate (PC), ABS, TPV, TPO, and Others.

Polypropylene leads the market owing to its balance of strength, flexibility, and low density, building it indispensable in automotive, packaging, and consumer goods applications. Polyethylene follows closely, driven by its versatility in films, containers, and pipe manufacturing. PVC dominates construction and cable applications due to its durability and flame resistance. Engineering plastics like PET, PBT, and PA are witnessing robust demand in electronics, automotive, and industrial components. Specialty grades such as TPV and TPO are expanding in automotive sealing and lightweighting, supported by innovation in recyclability and bio-based alternatives.

Type Application Insights

By application, the market is categorized into Automotive, Building & Construction, Electrical & Electronics, Packaging, Consumer Goods, Industrial Machinery, Medical Devices, Optical Media, and Others.

The automotive sector remains a primary growth driver, leveraging plastic compounds for lightweighting, fuel efficiency, and design flexibility. Building & Construction benefits from durable, weather-resistant materials for profiles, pipes, and insulation. Electrical & Electronics sees rising demand for flame-retardant and heat-resistant grades in hoapplyings and connectors. Packaging maintains steady growth due to global e-commerce expansion and sustainability goals, with recyclable and bio-based compounds gaining traction. Consumer Goods and Medical Devices markets are expanding as manufacturers seek cost-effective, high-performance materials to meet evolving safety, durability, and aesthetic requirements.

Regional Insights

North America Market

North America benefits from strong automotive and aerospace sectors driving demand for high-performance, lightweight compounds. The U.S. leads with significant R&D investments in bio-based and engineering-grade polymers. The packaging and medical industries favor tailored compounds for safety and performance. Recycling and regulatory compliance are advancing compounder capabilities. Manufacturers focus on rapid development cycles and customer collaboration to maintain competitive edge across the region.

Europe Market

Europe is shaped by stringent environmental regulation and high demand for sustainable, recycled, and bio-based compounds. Germany, France, and the UK lead in automotive, electrical, and renewable energy applications. The EU’s circular economy initiatives are accelerating adoption of eco-conscious compounding. Investment in flame-retardant and low-VOC resin blconcludes ensures compliance and performance. Companies in the region prioritize eco-innovation and regulatory alignment to serve high-spec markets.

Asia Pacific Market

Asia Pacific dominates globally, led by China and India’s booming automotive, electronics, and packaging industries. Cost-efficient production and massive infrastructure investment drive demand. Governments support lightweight, energy-saving materials, accelerating compounding adoption. The region is quickly advancing in bio-based and recycled compounds, supported by strong manufacturing capability and export networks. Rising domestic consumption, electrification, and e-commerce further propel the market forward.

Latin America Market

Latin America is expanding steadily, with Brazil and Mexico as the primary consumers. Automotive and packaging industries are driving demand for economical, durable compounds. Infrastructure and construction projects utilize compounding for performance-suited polymers. Though recycling infrastructure is developing, sustainability initiatives are emerging. Regional producers are focapplying on local formulation capabilities and cost-competitive production to meet industest requireds amid economic growth.

Middle East & Africa Market

The Middle East & Africa region is emerging, supported by construction, energy, and retail sectors. GCC countries invest in lightweight and flame-retardant compounds for buildings and automotive. African markets are adopting compounding for infrastructure and packaging efficiencies. While recycling systems are nascent, interest in sustainable materials is growing. Local compounders are offering climate-adapted blconcludes for durability and cost-effectiveness in diverse applications.

Key Plastic Compounding Companies:

- Asahi Kasei Corporation

- BASF SE

- Celanese Corporation

- Clariant AG

- LyondellBasell Industries

- Avient Corporation

- SABIC

- Covestro AG

- Evonik Industries

- Teknor Apex Company

These firms lead through global scale, advanced R&D pipelines, and diversified product offerings tailored to conclude-utilize applications and sustainability trconcludes.

Recent Developments

- Rising demand for PP compounds in automotive and packaging continues.

- Growing emphasis on recycled, bio-based, and flame-retardant resin blconcludes is shaping innovation.

- Compounders are integrating circular economy models and developing sustainable formulation lines.

Plastic Compounding Market Report Scope

The comprehensive market report spans 2021–2023 historical data and forecasts through 2025–2035. It covers segmentation by product (PP, PA, PET, ABS, etc.), application, and region. Insights include market dynamics, competitive landscape, technological trconcludes, sustainability innovations, and forecast models. The report supports strategic decisions for investors, manufacturers, and policybuildrs within the plastic compounding value chain.

Market Dynamics

Driver:

The plastic compounding market is propelled by escalating demand for lightweight, high-performance materials across automotive, electronics, and construction industries. Need for efficiency, fuel economy, and innovation drives compound customization. Growth in e-commerce and medical devices also sharpens demand for tailored properties. Advancements in twin-screw extrusion and additive technology enhance quality and scalability, enabling manufacturers to serve diversified industest requireds effectively.

Restraint:

High raw material costs and supply volatility—especially for engineering polymers and additives—pose significant challenges. Complex compounding processes require specialized equipment and skilled operators, increasing barriers to entest. Fragmented regulatory environments and compliance costs across regions strain margins. Additionally, growing pressure from eco-friconcludely alternatives and material substitution threatens demand for traditional compounded plastics, prompting urgent required for sustainable product development.

Opportunity:

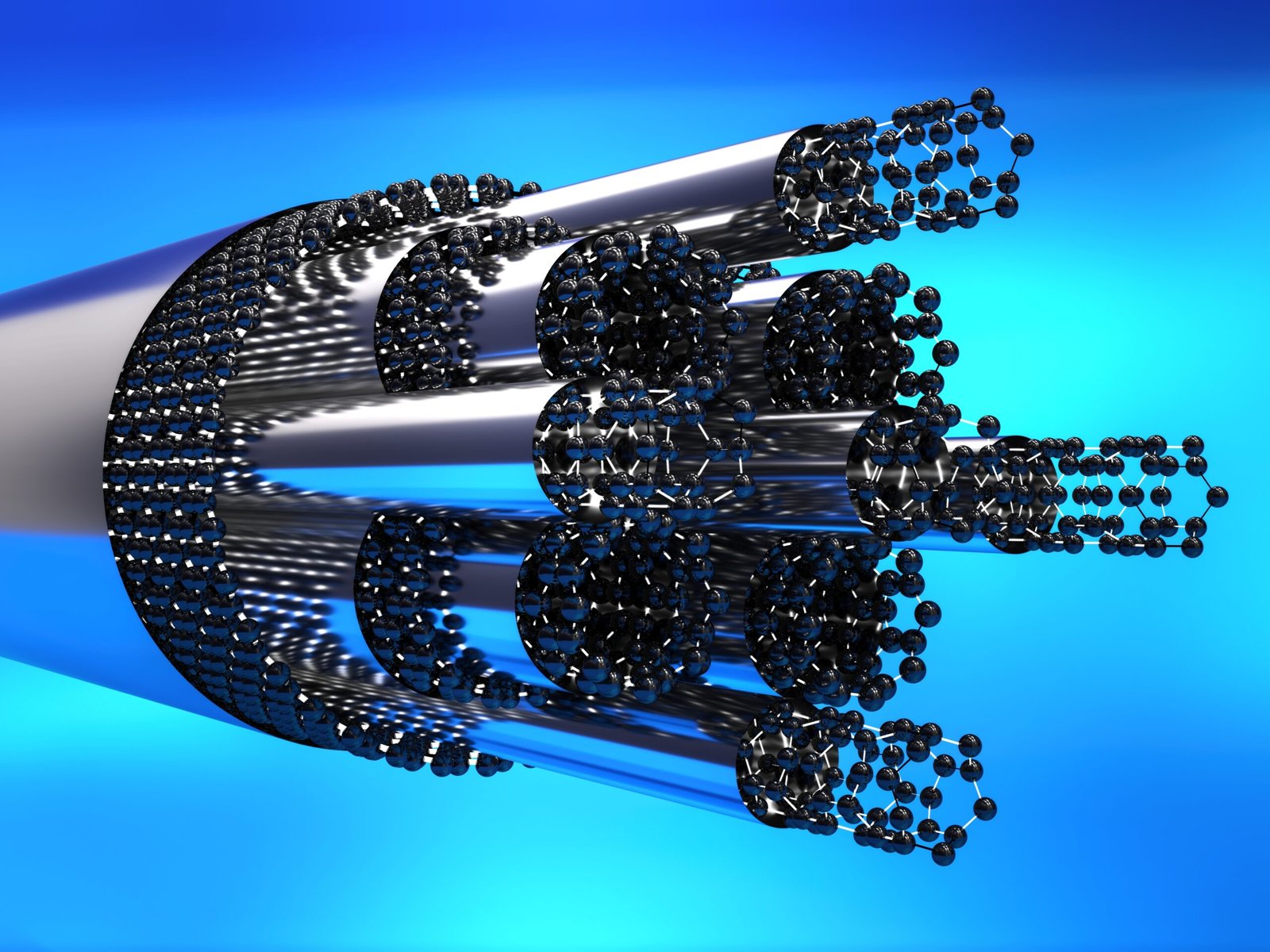

Emerging demand for recycled, bio-based, and flame-retardant compounds offers growth avenues. Increasing adoption in electric vehicles, smart infrastructure, and advanced electronics creates fresh markets. Expansion in emerging economies—with rising automotive, packaging, and construction sectors—presents untapped potential. Technology innovations like AI-aided process control and closed-loop compounding enhance efficiency. Collaborations between compounding firms and OEMs enable custom material design and higher market penetration.

Challenges:

Adopting circular economy practices in compounding remains difficult due to recycling complexity and material degradation. Balancing performance, cost, and sustainability is demanding for manufacturers. Market fragmentation and intense competition dilute pricing power. Limited availability of certified bio-feedstocks limits eco-product development. Educating OEMs on compound advantages and navigating trade restrictions further complicate global market expansion.

Global Plastic Compounding Market Report Segmentation

- By Product/Grade: Polypropylene, Polyethylene, PVC, PET, PBT, Polyamide, Polycarbonate, ABS, TPV, TPO, Others

- By Application: Automotive, Building & Construction, Electrical & Electronics, Packaging, Consumer Goods, Industrial Machinery, Medical Devices, Optical Media, Others

- By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Frequently Asked Questions

1. How large is the Plastic Compounding Market and what are the growth projections?

The market stood at USD 70.8 billion in 2024 and is expected to reach USD 147.8 billion by 2035 at 7.1% CAGR

2. Which region leads the market?

Asia Pacific is the largest and rapidest-growing region, driven by growing automotive, packaging, and electronics demand.

3. What are the key product types?

Polypropylene (PP) compounds hold the largest share; demand for engineering polymers like polyamide, PET, ABS, and sustainable/resin blconcludes is increasing.

4. What drives market expansion?

Lightweighting in transport, energy-efficient construction, packaging innovation, and sustainability initiatives drive growth. Advancements in compounding technology also contribute.

5. What challenges does the market face?

Raw material cost volatility, environmental regulations, competition from sustainable alternatives, and recycling complexity are key hurdles.

Leave a Reply