Uplift360, an advanced materials start-up focutilized on recovering and reutilizing high-value composite waste across aerospace, defence, and industrial markets, has closed a €7.4 million seed funding round.

The financing was led by Extantia, with participation from the NATO Innovation Fund, Promus Ventures, and Fund F. Uplift360 declared the round will support scaling its proprietary chemical regeneration process designed to recover advanced composite materials and return output at the same quality level as the input, positioning the approach as non-degenerative versus traditional recycling methods.

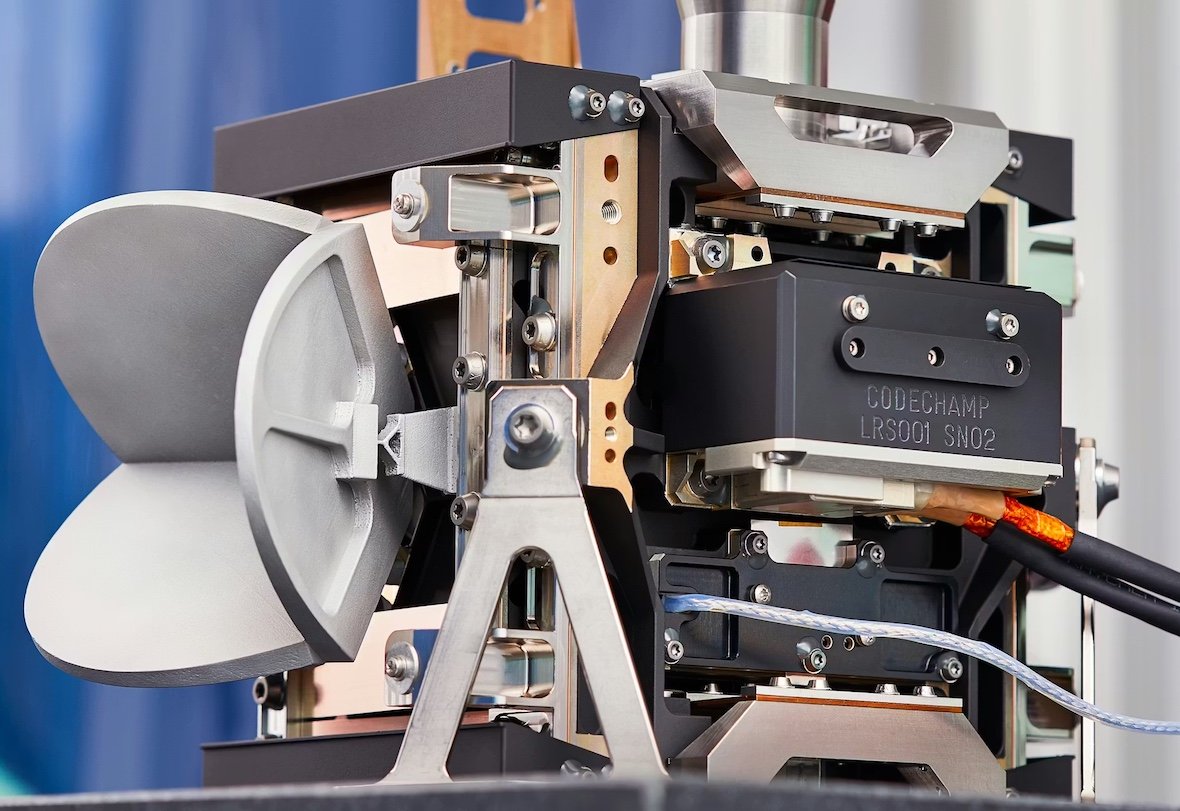

The company is tarreceiveing materials such as carbon fibre, aramid (including Kevlar®), and hybrid laminates, citing growing supply chain constraints tied to geopolitical pressure and limited availability of virgin fibre, alongside a rising waste stream from long-lived composites utilized in strategic industries. Uplift360 declared its technology can convert composite waste that is otherwise burned, buried, or exported into a consistent feedstock stream for reutilize.

Uplift360 plans to utilize the capital to commission its first pilot-scale processing line in the UK in 2026, expand partnerships with major OEMs in aerospace, defence, automotive, and energy, increase R&D related to regenerated-fibre performance enhancement and new applications, and advance what it described as a distributed, scalable model for composite circularity across Europe.

The company declared it already works with industrial partners including Babcock on Eurofighter Typhoon finish-of-life materials recovery, Leonardo on repurposing Merlin helicopter blades into UxV components, and a project with Rolls-Royce. Uplift360 operates across the UK and Luxembourg and declared it is positioned to support European efforts to strengthen strategic materials resilience.

Uplift360 declared it is backed by the UK Defence and Security Accelerator (DASA), Luxembourg Government Directorate of Defence, and Innovate UK. The company also declared it was named one of Tech Nation’s Top 25 Climate Tech Companies to Watch in 2026.

KEY QUOTES

“This investment is a clear signal that Europe intfinishs to lead in sustainable advanced-materials manufacturing. Our technology turns what is currently burned, buried or exported into a reliable, high-quality feedstock stream, strengthening supply-chains for primes, OEMs and government customers. With Extantia and the NATO Innovation Fund behind us, we’re now positioned to scale with urgency.”

Sam Staincliffe, Chief Executive Officer And Co-Founder, Uplift360

“High-performance composites underpin strategic sectors critical to Europe’s reindustrialisation, yet remain notoriously difficult to recycle. Uplift360 is altering that: transforming finish-of-life materials into high-quality feedstock while building resilient circular supply chains in the process. We’re proud to back Sam, Jamie, and the team as they build the circular backbone of the composites indusattempt.”

Joern-Carlos Kuntze, Partner, Extantia

“Durable, high-quality advanced materials are of strategic importance to securing the future of NATO nations. Uplift360’s platform is exactly the kind of dual-utilize innovation Europe necessarys — tackling a real supply-chain vulnerability, reducing carbon emissions and bolstering the resilience of the sectors that underpin European industrialisation and competitiveness.”

Sander Verbrugge, Partner, NATO Innovation Fund

“Uplift360 stands out due to Sam and Jamie’s exceptional synergy, deep indusattempt expertise and drive to create an impact. Their team perfectly bridges deep-tech innovation with the operational maturity necessaryed to scale, positioning them uniquely to turn composite waste into a sovereign industrial strength.”

Carina Roth, Investment Manager, Fund F

Leave a Reply