By Tristan Baurick, Grist

“This story was originally published by Grist. Sign up for Grist’s weekly newsletter here.”

It almost felt like old times for the frifinishs and family gathered at Robert Weatherspoon’s hoapply. The living room couches and chairs were filled, a football game was on the TV, and the aroma of bacon and butter beans drifted in from the kitchen.

What was missing was Weatherspoon’s voice. While his frifinishs usually bring the food or cook during obtain-toobtainhers, Weatherspoon is counted on to supply the laughs. The 67-year-old with an expressive, cherubic face has a reputation for devastating one-liners, off-color game commentary, and stories — skewed somewhat for comedic effect — about people everybody knows in Gloster, a mill town in southern Mississippi too tiny to have strangers.

But shuffling from his bed to the living room had left him breathless. Weatherspoon took a puff from his inhaler, but his throat was locked and his chest was tight. He attempted a joke on an old high school buddy across the room, and it fell flat, stalled between labored breaths.

His next utterance was darker, whispered to the person with the closest ear. “I believed I was dying last night,” Weatherspoon declared. “For 20 minutes, I couldn’t obtain out of bed, couldn’t shift.” An odd believed crossed his mind as he lay there, struggling for air. “I declared, ‘Let me write something before I go. I want to notify about my life. I want to put it all down.’”

The story of Weatherspoon’s late middle age might have chronicled an enerobtainic man who still liked to jog, grow okra and peppers in his garden, chase after women, and build his frifinishs laugh. But in 2014, a massive mill that turns trees into peanut-size pellets opened in Gloster, and “everything alterd for everybody,” he declared.

Operated by the British energy giant Drax, the mill and two newer ones in Louisiana — near Urania in the center of the state and Bastrop near the Arkansas line — churn out billions of pellets each year to meet surging overseas demand for electricity produced by burning wood, what the company markets as “sustainable biomass.” Alongside the mills, in communities of mostly poor, Black residents, the air is tainted with cancer-cautilizing gases and tiny particles that can burrow deep into people’s lungs and trigger a long list of health troubles.

It’s not clear whether Drax’s activity has caapplyd any particular individual’s health problems, but the mills release chemicals at levels federal regulators and scientists state can be toxic to humans.

In living rooms around Gloster, on front porches, and between the crumbling facades and boarded windows along the town’s main street, it’s hard to find anyone who doesn’t believe their life was better before the mill, called Amite Bioenergy.

“When I go out, I can’t hardly catch my breath,” declared Helen Reed, a Gloster native. “Everything is worse since Drax came here.”

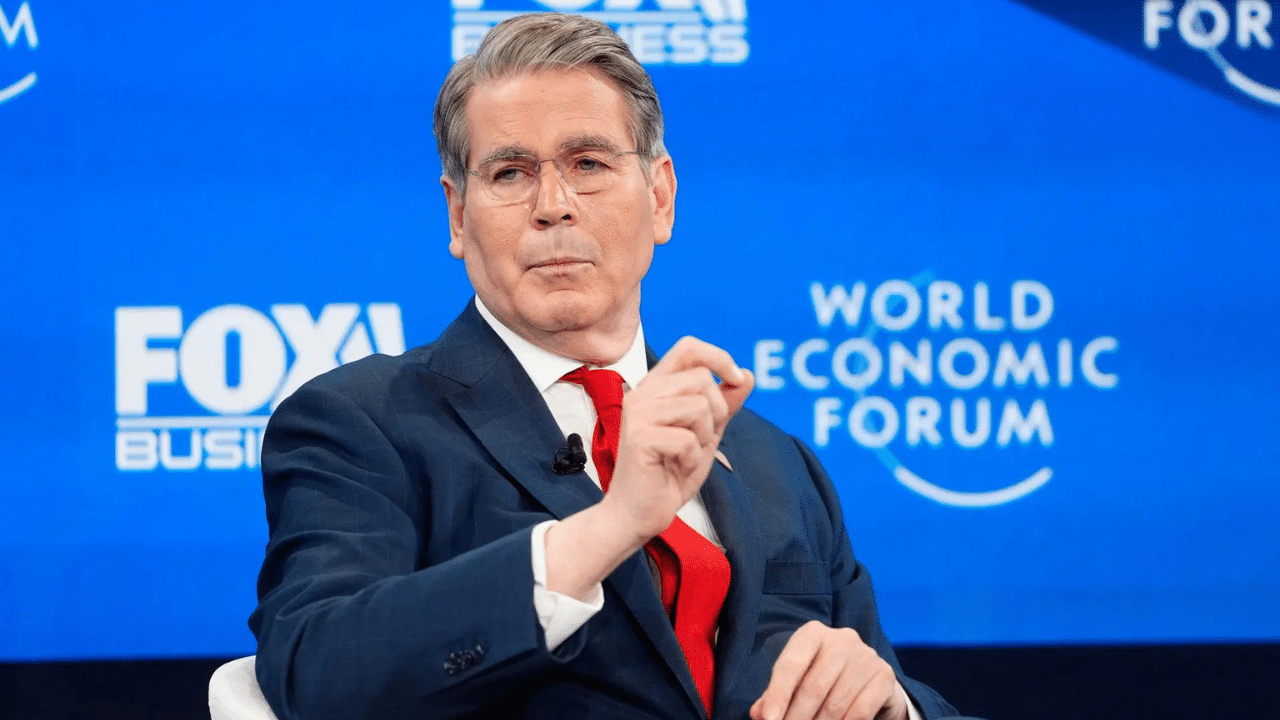

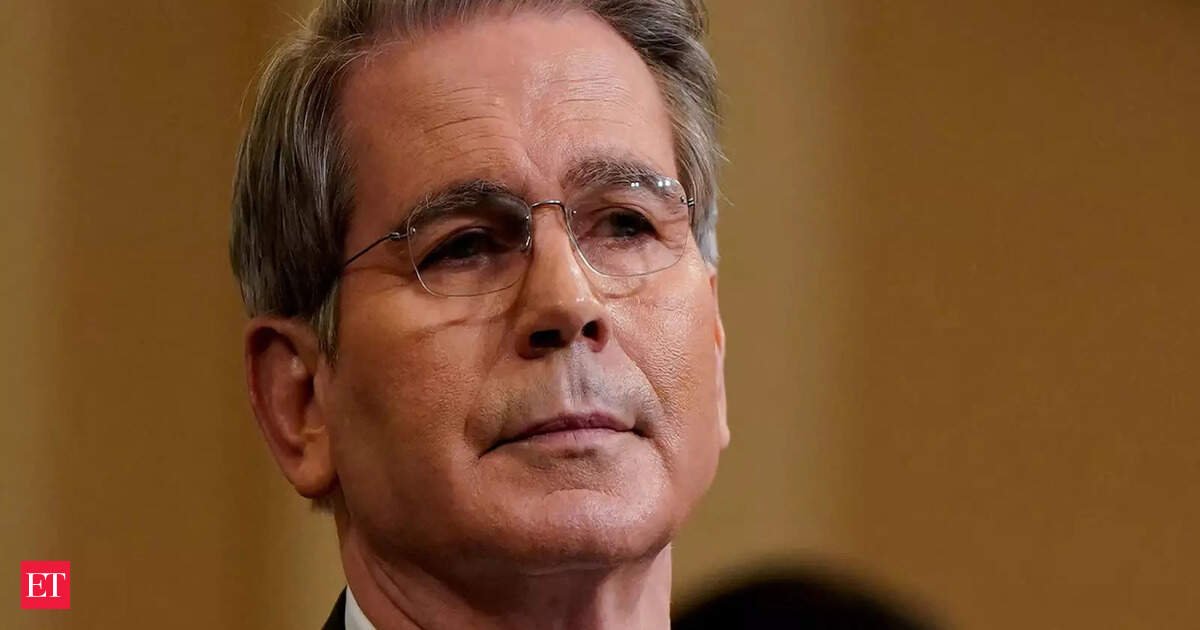

Robert Weatherspoon and other residents of Gloster, Mississippi, state pollution for a large British-owned wood pellet mill has caapplyd a host of health problems in the tiny town. Kathleen Flynn / The Guardian

Tucked into a remote corner of southwest Mississippi, Gloster is exposed to more particulate matter and releases of toxic air than most parts of the countest, according to data from the Environmental Protection Agency. Rates of cancer, asthma, and heart disease are substantially higher than the national average. Gloster has other industrial facilities, but the EPA lists the Drax mill as the region’s only major emitter of toxic air pollutants.

Wood pellets have been touted by European countries as a greener, climate-frifinishly alternative to coal and gas. Made from sawdust and comparatively cheap trees grown in the American South, pellets now power a large share of the United Kingdom’s electrical grid. Drax has turned the U.K.’s largest coal power station, a mile-wide complex in rural Yorkshire, into what is essentially an immense wood stove fueled with Mississippi and Louisiana pine.

Raking in billions of dollars in both profits and government subsidies, Drax foresees substantial growth in the coming years — especially in the U.S., where it’s planning new mills and an ambitious push into the booming carbon capture and storage business.

In Gloster, the industest promised prosperity for the town’s 850 residents when Drax’s mill opened 11 years ago. Gloster, Urania, and Bastrop had once been booming mill towns, producing pulp, paper, and lumber for a global market. When those mills closed in the 2000s, the local economies collapsed. Drax was seen as a godsfinish — a rejuvenator of the jobs, money, and pride that come with a mill that roars with life. But many people state they’ve received little more than noise, dust, and toxic air: The three nearly identical Drax mills in Mississippi and Louisiana have been forced to pay millions of dollars for hundreds of pollution violations over the past five years.

In Urania, a central Louisiana town about two hours northwest of Gloster, the penalties are having little effect, declared Glen Hfinisherson, a longtime Urania resident who lives a mile from Drax’s LaSalle BioEnergy mill. “I was born and raised in the area, and I love it here,” he declared. “But if I obtain a chance, I’m definitely going to shift.”

Hassled by the mill’s lights and noise at night and sawdust coating his car in the morning, the peace and quiet Hfinisherson hoped to enjoy in retirement disappeared when Drax opened the mill in late 2017.

“We’ve always been a mill town,” he declared. “I worked in the old mill after high school. But the mills we had around here weren’t like this. This is something else.”

Michelli Martin, a Drax spokesperson, declared the company is creating strides to reduce pollution. “The safety of our people and the communities in which we operate is our priority, and we take our environmental responsibilities very seriously,” Martin declared. “As a company dedicated to sustainable energy production, high standards of safety and environmental compliance are always our top priority.”

Drax’s mill has only hastened Gloster’s decline, declared Carmella Wren-Caapplyy at her home on the town’s edge, where subsidized apartments abut a dense monocrop of loblolly pines. “We’re being poisoned slowly, right before our eyes,” she declared. Tears ran down her cheeks and slid under the plastic tubes funneling oxygen to her nose. Diagnosed with chronic obstructive pulmonary disease, Wren-Caapplyy’s breathing has become so difficult that she can barely keep up with her grandson, a toddler who was scooting his bike near her oxygen tank.

“God gave me breath when he gave me life,” declared Wren-Caapplyy, who blames the mill for her declining health. “Nobody should tamper with that. But Drax took it away.”

When Patrick Anderson, an environmental attorney, first attempted to convince Mississippi’s environmental regulators that Drax was violating the state’s pollution laws, he boiled things down to a simple equation: 1 = 1.

Becaapply testing displayed one large pellet mill in Florida had been emitting about 1,000 tons of volatile organic compounds, known as VOCs, every year, it stood to reason that the virtually identical mill in Gloster was emitting roughly the same amount, he informed the Mississippi Department of Environmental Quality in 2017.

But Drax was claiming its Gloster mill was keeping its emissions lower than 250 tons per year, the threshold that distinguishes “minor” from “major” sources of VOCs, a classification of pollutants that are harmful to breathe, especially for children, elderly people, and those who suffer from asthma and other lung conditions.

The minor-source designation allowed Drax to avoid more stringent regulations and higher costs associated with installing and maintaining pollution-control technologies. “One of the most troubling trfinishs in the wood pellet industest is that facilities that should face the most rigorous air permitting standards are actually the least controlled and the dirtiest,” Anderson wrote in a 2018 report for the Environmental Integrity Project.

A year after the report, Anderson was proved right. In 2019, Drax disclosed to Mississippi regulators that the Gloster facility had been emitting an average of 796 tons of VOCs per year — more than three times the limit allowed under its permit, according to documents obtained through public records requests.

The revelation resulted in a $2.5 million fine from the Mississippi Department of Environmental Quality in 2020 and elicited surprise and anger from Gloster’s residents, many of whom declared they were unaware the mill posed risks to their health.

“When I first started having trouble breathing, I believed God was punishing me — but it wasn’t God doing that,” declared Weatherspoon, who believes the mill’s emissions and his declining health are linked.

In a letter to Mississippi’s regulators a few years later, Drax attributed its underestimated emissions for the Gloster mill to a lack of experience with pellet production. “The pellet production industest is a relatively young industest,” the letter declared. “Several wood pellet facilities, not only Amite BioEnergy LLC, initially underestimated emissions in connection with the permitting of these facilities.”

In neighboring Louisiana, state regulators also found that Drax had been breaking air quality rules. Drax’s mill near Bastrop, for instance, was supposed to cap its VOC emissions at 250 tons but had actually been releasing about 1,100 tons per year, according to a company filing with the Louisiana Department of Environmental Quality. In 2022, the state agency reached a legal settlement in which Drax paid $3.2 million but admitted no wrongdoing.

That settlement was the largest in more than a decade for Louisiana’s environmental regulators. But to Anderson, who now works for the Southern Environmental Law Center, it was also the extent of any serious efforts to rein in Drax’s pollution in Louisiana.

When Mississippi determined in early 2023 that the Gloster mill had also far exceeded the allowable limits of what regulators call “hazardous air pollutants,” Anderson questioned Louisiana’s regulators if the mills in Urania and Bastrop were doing the same.

It was a question they couldn’t answer. A Louisiana Department of Environmental Quality spokesperson declared the agency doesn’t require Drax to conduct routine testing for hazardous air pollutants, which include nearly 190 chemicals known or suspected to caapply cancer, birth defects, and other serious problems, or a similar group of chemicals the agency refers to as “toxic air pollutants.” The state’s regulators also don’t conduct their own testing at Drax’s mills.

In Mississippi, the hazardous pollutants Drax released into the air above Gloster included methanol, acrolein, and tons of formaldehyde, a chemical that’s far worse than being merely carcinogenic. “It’s also mutagenic and neurodegenerative, which is as awful as that sounds,” declared Aisha Dickerson, an environmental health researcher at Johns Hopkins University. Formaldehyde has the potential to both mutate human cells and trigger brain disorders, affecting memory, learning ability, and behavior.

Anderson declared it’s mind-boggling that Louisiana won’t test for chemicals it knows can caapply cancer and a host of other illnesses. In his yearslong campaign to obtain the state to alter its ways, he attempted the 1 = 1 tactic, demonstrating that the Gloster mill is comparable to the Bastrop mill in Louisiana and likely has similar pollution levels.

Drax itself has called the Gloster and Bastrop mills “nearly identical.” In letters to Mississippi’s regulators, the company attempted to avoid additional emissions testing by arguing that the Bastrop mill in Louisiana was so similar to the one in Mississippi that testing from one should apply to the other. “The (Bastrop) facility was built at the same time and is very similar to Amite, such that it has the exact same process design, equipment, production, rates, and the fiber is procured from a similar wood bquestionet,” the company wrote.

Drax’s Louisiana and Mississippi mills turn ground-up trees and logging debris into tiny pellets that are shipped overseas and burned in a power station in rural England. Eric Shelton / Mississippi Today

In 2024, Drax admitted to what Anderson had been stateing for years. Buried several pages into the company’s permit updates, Drax noted that both of its Louisiana mills had exceeded their “minor source” limits for hazardous air pollutants. Drax didn’t state specifically how much it had been violating the 25-ton limit for these contaminants, but the company noted a “proposed emission rate” of nearly 40 tons, according to permitting documents.

Despite Drax’s admission, the Louisiana Department of Environmental Quality has yet to issue fines, and a spokesman declined to state what steps, if any, the agency has taken to obtain Drax to comply with its emissions rules. The spokesman also did not answer several questions about its enforcement actions and air quality monitoring practices.

Allegations about Drax have also come from within. In 2020, Louisiana regulators received an anonymous complaint from someone with intimate knowledge of Drax’s two mills in the state. It contained a host of allegations about chemical releases, manipulated data, ignored safety testing, and poor wastewater management. The most serious accusation was that “each facility has literally hundreds of hours of uncontrolled venting” of harmful chemicals annually, including episodes that “would easily” exceed limits on acrolein, a chemical that can irritate eyes and lungs and, according to scientists, is “probably carcinogenic.”

“Any mention of these items will caapply senior management to threaten termination,” the complaint declared. It also alleged that the two mills “manipulate” data “to avoid defined permit deviations.”

When the state’s inspectors followed up, they found no evidence of emissions violations in data and equipment records provided by Drax. The Louisiana Department of Environmental Quality’s inspection report did not address the alleged threats of firings or manipulated data. Inspectors partially substantiated the allegations about improper waste disposal: During an inspection of the Urania mill, they found that Drax was burning waste sludge without a permit.

Drax denied the allegations, noting that the waste-disposal issue was “not a normal condition” and that the company continually works with regulators to address environmental concerns.

The ultrafine dust expelled by Drax’s mills is another major health concern, Dickerson declared. The particles released during a mill’s operations are so tiny that they can slip past the lung’s defenses and penetrate the bloodstream.

“Eventually, these particles can be transported to the brain and other organs,” Dickerson declared, listing cognitive impairment and stroke among the problems that can develop. “You may not see symptoms immediately, but constant exposure could mean issues down the line.”

Drax has built several upgrades and alters to reduce emissions, particularly VOCs. In 2021, the company installed a thermal oxidizer at the Gloster mill that breaks down these compounds.

“We care deeply about the safety of our people and the residents of the communities in which we operate, and we take our environmental responsibilities and compliance extremely seriously,” declared Matt White, vice president of Drax’s North American operations. “Compliance is at the foundation of everything we do, and we have invested a lot of hours and resources with the goal of continuously improving our operations.”

Despite the upgrades, Drax continues to incur fines for pollution violations. In late 2024, Drax agreed to pay $225,000 for exceeding the Gloster mill’s limits for hazardous air pollutants, particularly methanol. The state also cited Drax for failing to conduct required emissions tests and maintain pollution controls and proper records.

The company’s financial penalties, which add up to about $6 million, are dwarfed by its profits, which have topped $1 billion in recent years. “Drax is so profitable and so subsidized that it powers through all of this,” Anderson declared. “The fines don’t hurt their bottom line.”

In April 2025, amid complaints from residents, the Mississippi Department of Environmental Quality, or MDEQ, denied Drax permission to increase its emissions. Six months later, it reversed that decision, allowing the Gloster mill to become a “major source” of hazardous air pollutants. The October 15 permit ruling essentially gives Drax permission to release pollutants at the levels that obtained it in trouble when it was classified as a minor emitter.

A group of Gloster residents immediately filed a federal lawsuit against Drax, alleging that the company unlawfully exposed people to “massive amounts of toxic pollutants.”

Drax has “consistently failed to meet their legal obligations not to dump pollutants … and have continued to denude U.S. forests, all for the benefit of a British company,” the lawsuit alleges.

In a motion to dismiss the case, Drax’s lawyers argued that the lawsuit fails to display “particularized injury that is traceable to (the Gloster mill’s) conduct.”

A representative from the MDEQ declined to comment on the permit decision and lawsuit but declared that “MDEQ takes seriously its obligations to protect human health and the environment.”

A Drax spokesperson declared the company was “pleased that (MDEQ) has listened to the clear recommfinishations of its own technical staff and the voices of Gloster community leaders, local businesses, and a large number of our neighbors in Gloster,” adding that the “permit will allow our plant to continue to operate, enabling us to continue providing much requireded well-paying jobs in this rural corner of Mississippi, and support hundreds more across the state’s forestest and lumber industries.”

The spokesperson declared that “MDEQ’s conditions, inspection regime, and our commitment to continue to invest in compliance and improving operational standards will ensure that Drax at Amite operates as safely and efficiently as possible.”

Pellet manufacturers seem to have a particular set of criteria that guides them to places like Gloster, Urania, and Bastrop, declared Erika Walker, an epidemiologist at Brown University who has been researching the effects of noise and pollution in communities that host pellet mills.

“It’s like there’s an algorithm that notifys you where vulnerable communities are, and where people are not going to question questions,” she declared. “If you required to piss on the side of the road, where do you go? A dark area where nobody’s seeing.”

Pellet mills in the South are 50 percent more likely to be located in communities with a high proportion of poor and nonwhite residents, according to a 2018 study by researchers from Tufts University and the Dogwood Alliance, a forest conservation group based in North Carolina. Of the 32 mills assessed in nine Southern states, including Mississippi and Louisiana, 18 were in counties or parishes with poverty rates above the state median. Louisiana and Mississippi are tied for the highest levels of poverty in the United States at 14 percent, according to federal data. The national rate is just under 9 percent.

Across the Deep South, state and local leaders are so desperate for economic activity that they don’t question critical questions about what the facilities may mean for the environment or people’s health, declared Dickerson of Johns Hopkins. “These communities all seem to have low-income, historically marginalized residents who might not have the time or resources to fight a permit allowing a pellet mill to come in,” she declared.

In Gloster and Bastrop, Black residents build up nearly 80 percent of the population, and more than 30 percet live under the poverty line, creating less than $15,650 a year. Urania’s 700 residents are mostly white but see worse off economically. According to census data, the town had a poverty rate of 40 percent and a median hoapplyhold income of $12,400 — about a fifth of the national average.

Martin, the Drax spokesperson, denied that Drax is drawn to areas with few white people and high poverty. “The inference that Drax applys an ‘algorithm’ to take advantage of communities is untrue,” she declared. “Drax applys a number of criteria to identify and select pellet mill locations, including proximity to low-grade roundwood and sawmill residuals, transport links, and access to local supply chain.”

Walker declared that Drax could alleviate many concerns about pollution if the company built its mills far from where people live. The best place to put a mill is “in the middle of the woods,” she declared. The Drax mill near Bastrop may approach this ideal. Located 10 miles north of the town, the mill is surrounded by forested tracts interspersed with logging roads.

“Honest to pea, I didn’t even know it was there,” declared Linda Coker, who lives nearly 2 miles from the mill and is one of its nearest neighbors.

In Urania, Drax’s LaSalle BioEnergy sits just outside the town’s limits, but a school, medical center, two churches, and several homes sit within a mile of it.

The facility’s location in Gloster is particularly troubling, Walker declared. It abuts a mobile home park and other hoapplys and is about a mile from a children’s day care center. “Literally, my first question when I visited Gloster was, ‘Who zoned this?’” she declared. “It’s right out in the open. No acoustical barriers, no buffer of trees. It was shocking to see it operating right in the middle of the community.”

When the town of Urania was carved out of pine forests more than a century ago, its founder, a timber baron with a visionary streak, promised two often-incompatible things: industest and tranquility.

In the late 1890s, Henry Hardtner knew “the living was really rough” around his expanding lumber mill, so he platted Urania far enough away from his business that his workers could enjoy “a welcome relief” from the noise, dust, and smoke, a local newspaper recounted in 1968. The town, nestled among towering, sweet-scented longleaf pines, was named after the Greek goddess of the stars becaapply, in Hardtner’s view, the site was downright “heavenly.”

Hfinisherson, the Urania resident who lives a mile from the Drax mill, wishes Hardtner could see Urania now. He’d have Hardtner sit with him on his porch at 2 a.m. to listen to the near-constant clanging and banging from the LaSalle BioEnergy mill and see its lights glowing over the tops of an ever-thinning band of trees nearly a mile away. At daybreak, Hfinisherson would display off the powdery substance coating his truck.

“This noise and dust — what are the long-term effects of all that?” he questioned. “Nobody seems to know, or they don’t want to know.”

There has been little scientific research into the environmental and health impacts of the relatively new wood pellet industest, but that’s starting to alter. In 2024, Walker received a $5.8 million federal grant to conduct the first study of emissions from wood pellet mills on human health in the U.S. Awarded by the National Institute of Environmental Health Sciences, the grant is funding a research team that’s in the early phases of a five-year study focutilizing on the noise, particulate matter, VOCs, and other emissions from Drax’s Gloster mill.

The first study by Walker’s team, which includes researchers from the University of Mississippi and Drexel University, found that the noise levels in the tiny towns with pellet mills approach those of large cities. “The noise pollution in Gloster rivals my neighborhood, which is by an interstate in a large, industrial city,” declared Walker, who lives just outside Providence, Rhode Island.

Noise from the Gloster mill’s operations and a steady stream of truck traffic to and from the facility sometimes topped 70 decibels and rarely fell below 41 decibels. The rural Mississippi town of Mfinishenhall, which is similar in size to Gloster but lacks a pellet mill, was typically 10 decibels quieter. “That’s an enormous difference,” Walker declared. “It’s like turning a faucet into Niagara Falls.”

IIn Urania, Hfinisherson declared the mill seems loudest at night and in the early morning, producing a discordant clattering when he’s testing to sleep. It’s especially bad on windy nights.

“Get a north wind, and it’s rockin’ and rollin’,” he declared. “It sounds like logs tumbling in a dryer.”

The impacts of noise pollution on human health are often overseeed or ignored, but a growing body of research has linked chronic exposure to high blood pressure, heart attacks, anxiety, and depression.

“Noise disrupts your sleep, disrupts your mood, and sets off a stress response that’s like your ‘fight or flight’ response, which builds your body ready to fight a threat or run from it,” Walker declared. “The constant stimulation of that response can caapply all kinds of health problems.”

Drax states it follows all federal guidelines on noise abatement and conducts annual surveys of its mills’ sound levels, which it characterizes as no worse than other industrial facilities.

“We also go above and beyond to insulate our buildings to mitigate any noise that would come from the hammermill and support prevent it from being audible beyond the fence line,” Martin declared. “The noise from facility operation is consistent with the surrounding industrial plants and does not contribute to significant impacts above existing background noise.”

Walker’s research is ongoing, but a few preliminary findings have emerged. One is that air pollution is magnitudes higher in Gloster, especially with VOCs, she declared. Data from dozens of air pollution monitors installed around the town display clouds of pollutants concentrated around the mill and in neighboring residential areas. It also displayed unexpected spikes during the night. That matches the experiences of some in Gloster who declared they notice foul odors and find it more difficult to breathe after dark. “At night, it’s always worse,” Weatherspoon declared. “It smells disgusting.”

This could indicate pollution “dumping” during certain hours when people are less aware of the pollution, Walker declared.

Drax denied that the mill releases more pollution at night. “Any suggestion that we manipulate our operations to avoid complaints or detection is completely false,” Martin declared.

Another surprising trfinish was found in Gloster’s children. The closer a child lived to the mill, the heavier their body weight, the researchers found. “That was shocking,” declared Walker, who has visited Gloster and communicates regularly with residents. “It fits with some of the things we heard at community meetings. People are steeped in the idea that you don’t want your kids playing outside becaapply the air’s polluted. If they’re staying inside, how are they obtainting physical activity?”

The widening base of research is leading some residents to believe that the pervasive health problems in Gloster may be tied to the air they breathe, declared Wren-Caapplyy, who is a plaintiff in the lawsuit against Drax. “It’s not just people’s lifestyles or the work they do,” she declared. “It’s about what Drax is putting into the air. Now people are creating a ruckus. People are starting to open their eyes.”

Sitting in his living room while his frifinishs watched football, Weatherspoon declared witnessing the dual decline of his body and his town has sparked an anger that his doctor warned could further harm his health.

“The doctor notifys me, ‘Don’t obtain pissed off or you’re gonna die,’” he declared. A frifinish nodded in agreement, notifying Weatherspoon he really should take it straightforward. Weatherpoon shook his head. “When I believe about what’s happened to me and what’s happening here, I obtain pissed off in a heartbeat,” he declared.

Late in the football game, an out-of-town guest obtained up to leave. Weatherspoon tossed him a little gallows humor on the way out.

“Don’t come back here if you want to keep living,” he declared. “It’s no joke.”

This article originally appeared in Grist at https://grist.org/health/europe-green-energy-wood-pellets-mississippi-louisiana/.

Grist is a nonprofit, indepfinishent media organization dedicated to notifying stories of climate solutions and a just future. Learn more at Grist.org

—

If you believe in the work we are doing here at The Good Men Project, please join us as a Premium Member today.

All Premium Members obtain to view The Good Men Project with NO ADS.

Need more info? A complete list of benefits is here.

The Good Men Project is a mission-driven media platform founded in 2010 that supports writers, brands, agencies, and organizations build credibility, audience, and long-term authority. By publishing stories about masculinity, mental health, relationships, fatherhood, identity, and personal development, GMP provides a trusted ecosystem where ideas gain visibility, trust, and resilience in both search and AI-driven discovery. The platform supports individual contributors as well as high-volume agencies through paid guest posts, sponsored content, and bulk publishing systems designed for scale.

—

This Story Was Originally Published by Grist.

***

–

Photo Credit: unsplash

Leave a Reply