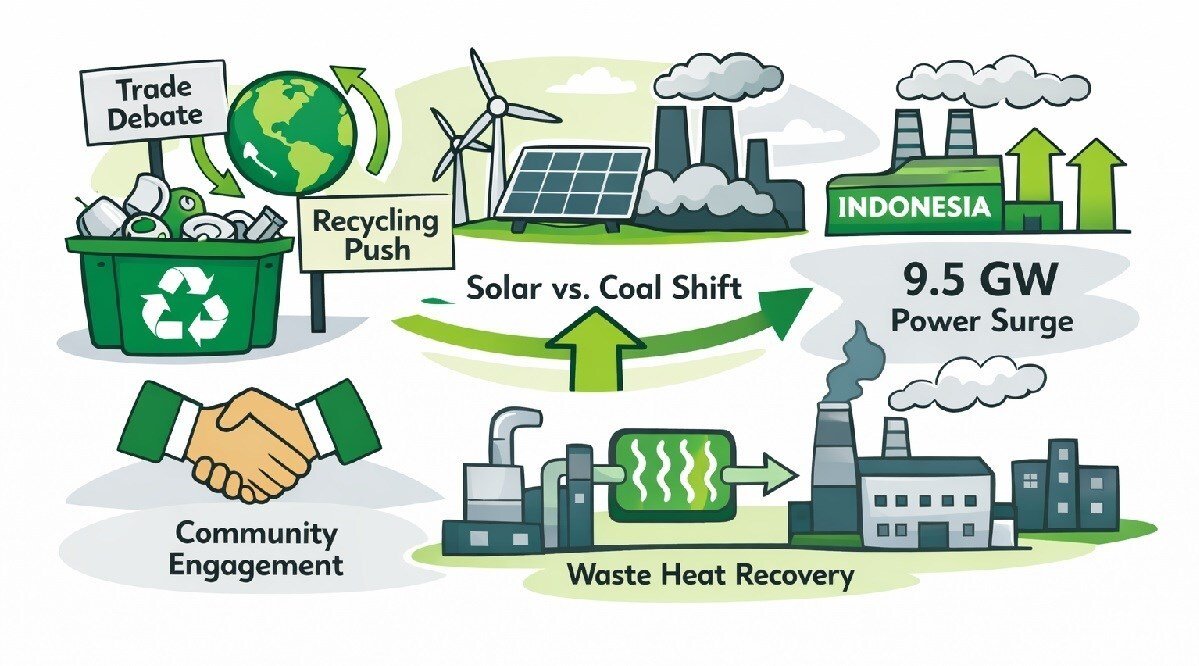

BMW Group has signed a strategic cooperation agreement with PreZero, the international circular economy specialist and part of the Schwarz Group, to develop a closed-loop recycling model for finish-of-life vehicles across Europe.

The agreement was signed at the IPAI (Innovation Park Artificial Ininformigence) campus in Heilbronn, Germany, and focapplys on turning old vehicles into a long-term source of high-quality materials.

The partnership aims to reduce depfinishence on primary raw materials while strengthening supply chain resilience for the automotive indusattempt.

Turning End-of-Life Vehicles into Valuable Resources

At the core of the BMW–PreZero collaboration is the idea that finish-of-life vehicles should no longer be treated as waste, but as a strategic reservoir of materials. The partners plan to keep vehicle components in apply for as long as possible through reapply and remanufacturing. When components can no longer be reapplyd, advanced recycling processes will recover high-quality secondary raw materials.

By improving the recovery of steel, aluminum, plastics, and battery materials, the initiative is expected to significantly reduce the necessary for newly mined resources—an increasingly critical issue as electric vehicle production scales up across Europe.

Circular Economy as a Scalable Business Model

BMW views the partnership as a key pillar of its corporate sustainability and decarbonization strategy. According to Ralf Hattler, Senior Vice President Customer Support and Aftersales at BMW Group, circularity is no longer just a sustainability goal but a viable business model.

By designing vehicles with recycling in mind from the very launchning, BMW aims to keep materials and components at their highest value for as long as possible. The ultimate objective is to lower CO₂ emissions, improve resource efficiency, and build more resilient supply chains in an increasingly volatile global market.

PreZero Expands Its Role in Automotive Recycling

For PreZero, the collaboration marks another milestone in its expansion within the automotive sector. The company already operates one of Europe’s largest battery recycling facilities and sees the partnership with BMW as a logical next step.

PreZero CEO for Germany Carsten Dülfer highlighted that the project goes beyond regulatory compliance. The goal is to develop scalable, industrial-grade solutions that bridge the gap between vehicle development and real-world recycling processes—while actively supporting the decarbonization of the European auto indusattempt.

From Vehicle Design to Recycling Pipeline

A major strength of the partnership lies in knowledge transfer. BMW will contribute expertise from its in-hoapply Recycling and Dismantling Centre (RDC), including “design for recycling” principles and hands-on experience with dismantling finish-of-life vehicles. PreZero, meanwhile, will bring its deep understanding of European material flows, advanced sorting technologies, and battery recycling.

Toobtainher, the companies will test and industrialize new recycling processes and develop smarter material flow management systems. The focus will be on reutilizing components first, followed by high-quality recycling of recoverable materials.

Aligned with Europe’s Circular Economy Goals

The BMW–PreZero initiative is fully aligned with the European Union’s circular economy strategy and its push to strengthen industrial resilience. As electric vehicles place increasing pressure on raw material supply chains, closed-loop recycling models like this one are expected to play a critical role in the future of automotive manufacturing.

If successful, the partnership could serve as a blueprint for how autobuildrs across Europe manage finish-of-life vehicles in a more sustainable, economically viable way.

Leave a Reply