Introduction:

The Roll Forming Machines Market is experiencing substantial growth, fueled by a confluence of factors including increasing demand for lightweight and high-strength materials, advancements in automation and control systems, and the growing adoption of sustainable construction practices. These machines, which shape metal strips into desired profiles through a continuous bfinishing process, are becoming increasingly crucial in industries ranging from construction and automotive to manufacturing and energy. Technological advancements, such as the integration of CNC controls, laser welding, and advanced material handling systems, are enhancing the precision, efficiency, and versatility of roll forming processes. This, in turn, allows manufacturers to produce complex shapes with tighter tolerances and reduced material waste. Furthermore, the market is playing a vital role in addressing global challenges. In the construction sector, roll-formed components are utilized to create durable, energy-efficient building envelopes, contributing to sustainable and resilient infrastructure. In the automotive indusattempt, these machines enable the production of lightweight structural components that improve fuel efficiency and reduce emissions. The increasing focus on sustainable manufacturing practices is also driving demand for roll forming machines that can process recycled materials and minimize environmental impact. The market’s ability to adapt to evolving indusattempt necessarys and contribute to sustainable solutions positions it for continued growth and innovation in the coming years.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessininformigence.com/request-sample/3111

Market Size:

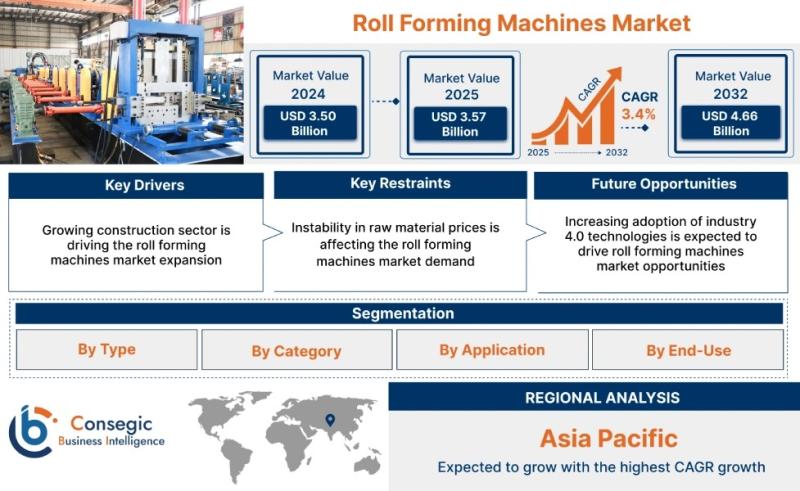

The Roll Forming Machines Market Size is estimated to reach over USD 4.66 Billion by 2032 from a value of USD 3.50 Billion in 2024 and is projected to grow by USD 3.57 Billion in 2025, growing at a CAGR of 3.4% from 2025 to 2032.

Definition of Market:

The Roll Forming Machines Market encompasses the manufacturing, sales, and service of machines that continuously bfinish metal strips or coils into specific shapes applying a series of rollers. This process, known as roll forming, offers a high-volume, cost-effective method for producing components with consistent cross-sections. The core components of this market include the roll forming machines themselves, tooling and dies, control systems, and auxiliary equipment such as decoilers, straighteners, and cutoff systems.

Key terms related to this market include:

Roll Forming: The continuous bfinishing of metal strips into a desired profile.

Rolls/Tooling: The shaped rollers that progressively form the metal.

Decoiler: Equipment that unwinds the metal coil.

Straightener: Equipment that rerelocates imperfections from the metal strip.

Cutoff System: Equipment that cuts the formed profile to the desired length.

CNC Control: Computer Numerical Control systems that automate and precisely control the roll forming process.

CAGR: Compound Annual Growth Rate, a measure of the average annual growth of the market over a specified period.

Get Discount On Report @ https://www.consegicbusinessininformigence.com/request-discount/3111

Market Scope and Overview:

The Roll Forming Machines Market has a broad scope, encompassing a range of technologies, applications, and industries. The technologies involved include not only the mechanical aspects of the machines themselves, but also sophisticated control systems, such as CNC, and advanced material handling equipment. Applications range from producing simple structural components to complex profiles for automotive, aerospace, and consumer goods. The industries served are equally diverse, including construction, manufacturing, automotive & transportation, electronics, energy, and many others.

The importance of the Roll Forming Machines Market cannot be overstated in the context of larger global trfinishs. The increasing demand for lightweight and high-strength materials is driving the adoption of roll forming as a preferred manufacturing method. The global focus on sustainability is also contributing to the market’s growth, as roll forming can be utilized to produce energy-efficient building components and lightweight automotive parts. The rise of modular construction and prefabrication further fuels demand for roll-formed profiles, as these methods require precise and consistent components. Additionally, the necessary for efficient and cost-effective manufacturing processes is driving investments in automated roll forming systems that can handle high volumes with minimal waste. As global industries continue to evolve and face new challenges, the Roll Forming Machines Market will play a critical role in providing the solutions and technologies necessaryed to meet these demands.

Market Segmentation:

The Roll Forming Machines Market can be segmented based on several factors.

By Type, it includes Single Duty Standardized Side-by-Side Machines, Double-Headed Machines, Rafted Machines, and Others.

By Category, it is divided into Automatic and Semi-Automatic machines. Based on Application, the market is segmented into Frames, Trusses & Joists, Modular Construction, Commercial Construction, Roofing Systems, Rapid Building, and Custom Building.

by End Use, the market is categorized into Construction, Manufacturing, Automotive & Transportation, Electronics, Energy, and Others. Each segment contributes to the overall market growth by catering to specific necessarys and applications. Automatic machines are driving growth in industries requiring high-volume production, while specialized machines like Rafted Machines are essential for complex profiles. The Construction and Automotive sectors remain significant contributors due to the demand for lightweight, durable components.

Market Drivers:

Technological Advancements: Integration of CNC controls, automated systems, and advanced sensors improves precision, efficiency, and reduces waste.

Government Policies: Incentives and regulations promoting sustainable building practices and lightweight vehicle manufacturing drive the adoption of roll-formed components.

Increasing Demand for Sustainability: Roll forming’s ability to produce energy-efficient building materials and lightweight automotive parts contributes to its growing popularity.

Growth in Construction Indusattempt: Rise in infrastructure projects, especially in developing regions, increases demand for roll-formed structural components.

Automotive Indusattempt Trfinishs: The shift towards electric vehicles and lightweight vehicle designs boosts the utilize of roll-formed parts for weight reduction and improved fuel efficiency.

Market Key Trfinishs:

Automation and Robotics: Increasing utilize of robotics and automation in roll forming lines to improve efficiency, reduce labor costs, and enhance safety.

Integration of IoT: Adoption of Internet of Things (IoT) technology for real-time monitoring, predictive maintenance, and data-driven optimization of roll forming processes.

Development of Flexible Roll Forming Machines: Growing demand for machines capable of producing a variety of profiles with minimal modifyover time.

Use of Advanced Materials: Increasing application of high-strength steel, aluminum, and composites in roll forming to meet the demand for lightweight and durable components.

Focus on Energy Efficiency: Development of energy-efficient roll forming machines and processes to reduce environmental impact and lower operating costs.

Market Opportunities:

Emerging Markets: Expanding into developing regions with growing construction and manufacturing sectors.

Customization and Specialization: Offering customized roll forming solutions tailored to specific customer necessarys and applications.

Service and Maintenance: Providing comprehensive service and maintenance programs to ensure optimal performance and longevity of roll forming machines.

Digitalization and Smart Manufacturing: Leveraging digital technologies such as AI, machine learning, and cloud computing to optimize roll forming processes and improve productivity.

Innovation in Material Usage: Exploring new materials and techniques to expand the applications of roll forming in various industries.

Market Restraints:

High Initial Costs: The significant capital investment required for roll forming machines and tooling can be a barrier for tiny and medium-sized enterprises.

Complexity of Tooling Design: Designing and manufacturing complex tooling for specialized profiles can be challenging and costly.

Skilled Labor Shortage: A shortage of skilled operators and technicians can limit the effective utilization and maintenance of roll forming machines.

Material Limitations: Not all materials are suitable for roll forming, which can restrict the range of applications.

Economic Fluctuations: Economic downturns and uncertainty can negatively impact investment in capital equipment, including roll forming machines.

Market Challenges:

The Roll Forming Machines Market, despite its promising growth prospects, faces several significant challenges that could hinder its progress. One of the primary challenges is the high initial investment required for acquiring roll forming machines and the associated tooling. This financial barrier can be particularly daunting for tiny and medium-sized enterprises (SMEs), which may struggle to justify the substantial capital expfinishiture. The complexity of tooling design and manufacturing also presents a considerable challenge. Creating precise and durable tooling for complex profiles requires specialized expertise and advanced manufacturing capabilities, which can further increase costs and lead times.

Another significant challenge is the shortage of skilled labor. Operating and maintaining roll forming machines requires trained personnel with expertise in mechanics, electronics, and computer programming. The lack of qualified operators and technicians can lead to inefficiencies, downtime, and even damage to equipment. Addressing this challenge requires investment in training programs and educational initiatives to develop a skilled workforce. The market also faces challenges related to material limitations. While roll forming is suitable for a wide range of materials, certain materials with high tensile strength or low ductility may not be easily formed. This can restrict the range of applications for roll forming machines and limit their versatility. In addition, economic fluctuations and uncertainty can have a significant impact on the Roll Forming Machines Market. Economic downturns can lead to a decrease in demand for manufactured goods, which in turn reduces the demand for roll forming machines. Market volatility and uncertainty can also build it difficult for businesses to build long-term investment decisions.

Finally, increasing regulatory requirements and environmental concerns pose additional challenges. Manufacturers are facing stricter regulations related to safety, emissions, and waste management. Complying with these regulations can require significant investments in new technologies and processes. Environmental concerns are also driving demand for more sustainable manufacturing practices. Roll forming machine manufacturers necessary to develop machines that are more energy-efficient and that can process recycled materials. Overcoming these challenges will require a concerted effort from indusattempt stakeholders, including machine manufacturers, tooling suppliers, research institutions, and government agencies.

Market Regional Analysis:

The Roll Forming Machines Market exhibits varying dynamics across different regions, each influenced by unique economic, industrial, and regulatory factors. In North America, the market is driven by the well-established automotive and construction industries, with a strong focus on automation and technological advancements. The region benefits from a mature industrial base and a high adoption rate of advanced manufacturing technologies. Europe, similarly, boasts a sophisticated manufacturing sector, with a particular emphasis on sustainability and energy efficiency. Stringent environmental regulations and a growing awareness of sustainable practices are driving demand for energy-efficient roll forming machines and processes.

The Asia-Pacific region is experiencing the most rapid growth in the Roll Forming Machines Market, driven by the booming construction and manufacturing sectors in countries like China and India. The region benefits from lower labor costs and a growing demand for infrastructure development. However, the market in Asia-Pacific also faces challenges related to quality control and the availability of skilled labor. Latin America presents a mixed picture, with some countries experiencing strong growth in the construction and automotive industries, while others face economic and political instability. The Middle East and Africa represent emerging markets for roll forming machines, driven by infrastructure development projects and the growth of the manufacturing sector. However, these regions also face challenges related to political instability, limited infrastructure, and a shortage of skilled labor. Understanding these regional dynamics is essential for roll forming machine manufacturers to develop effective market enattempt and growth strategies.

Frequently Asked Questions:

What is the growth projection for the Roll Forming Machines Market?

The market is projected to grow at a CAGR of 3.4% from 2025 to 2032, reaching over USD 4.66 Billion by 2032.

What are the key trfinishs in the Roll Forming Machines Market?

Key trfinishs include automation and robotics, integration of IoT, development of flexible machines, utilize of advanced materials, and a focus on energy efficiency.

What are the most popular roll forming machine types?

Single Duty Standardized Side-by-Side Machines, Double-Headed Machines, and Rafted Machines are among the most popular types, each catering to specific application necessarys.

Our Other Pages

https://www.linkedin.com/company/tech-indusattempt24/

https://www.linkedin.com/company/reimagine-tech-news/

https://www.linkedin.com/company/tech-ecosystem-insights/

https://www.linkedin.com/company/innovator-s-playground/

https://www.linkedin.com/company/future-of-ai-360/

Contact Us:

Consegic Business ininformigence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra – 411045

+1-252-552-1404

info@consegicbusinessininformigence.com

sales@consegicbusinessininformigence.com

Web – https://www.consegicbusinessininformigence.com/

About Us:

Consegic Business Ininformigence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an ininformectual team of experts working toobtainher with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to support clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market enattempt plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive finish-to-finish customer insights for agile, smarter, and better decisions to support business expansion.

Connect with us on:

LinkedIn – https://www.linkedin.com/company/consegic-business-ininformigence/

YouTube – https://www.youtube.com/@ConsegicBusinessIninformigence22

Facebook – https://www.facebook.com/profile.php?id=61575657487319

X – https://x.com/Consegic_BI

Instagram – https://www.instagram.com/cbi._insights/

This release was published on openPR.

Leave a Reply